FREE SERVICES

Learn about our free services

Our free services are available to all manufacturing SMEs across all regions of the UK. We offer free services in six different areas including IoT Sensor Solutions, Energy Insight Dashboards, Process Time Tracker, 3D Factory Simulations, HyperSpectral Scan Service and our Additive Manufacturing Service.

.

Learn about our IoT Sensor Solutions

IoT Sensor Solutions to Monitor your Factory

- Monitor equipment, manufacturing processes and environmental conditions within your facility.

- Analysis of the data assist in identifying energy usage at individual machine level, monitor machine utilisation and performance, ensure your factory environment is optimal and in compliance with environmental regulations.

- With a range of sensors from Power Monitoring, Temperature Monitoring, Air Quality Monitoring, Downtime Capture, Job Tracking and Air Particle Monitoring.

Learn about our Energy Insights Dashboard

Energy Insights Dashboard

- SMDH Energy Insights is your key to understanding, optimising, and harnessing the full potential of your energy usage. Our suite of cutting-edge Manufacturing Energy Insights dashboards empowers businesses to make informed decisions, reduce costs, and enhance sustainability.

- With three manufacturing dashboards available you can choose from Energy Insights, Energy Benchmarking and our Energy Impact Tracker.

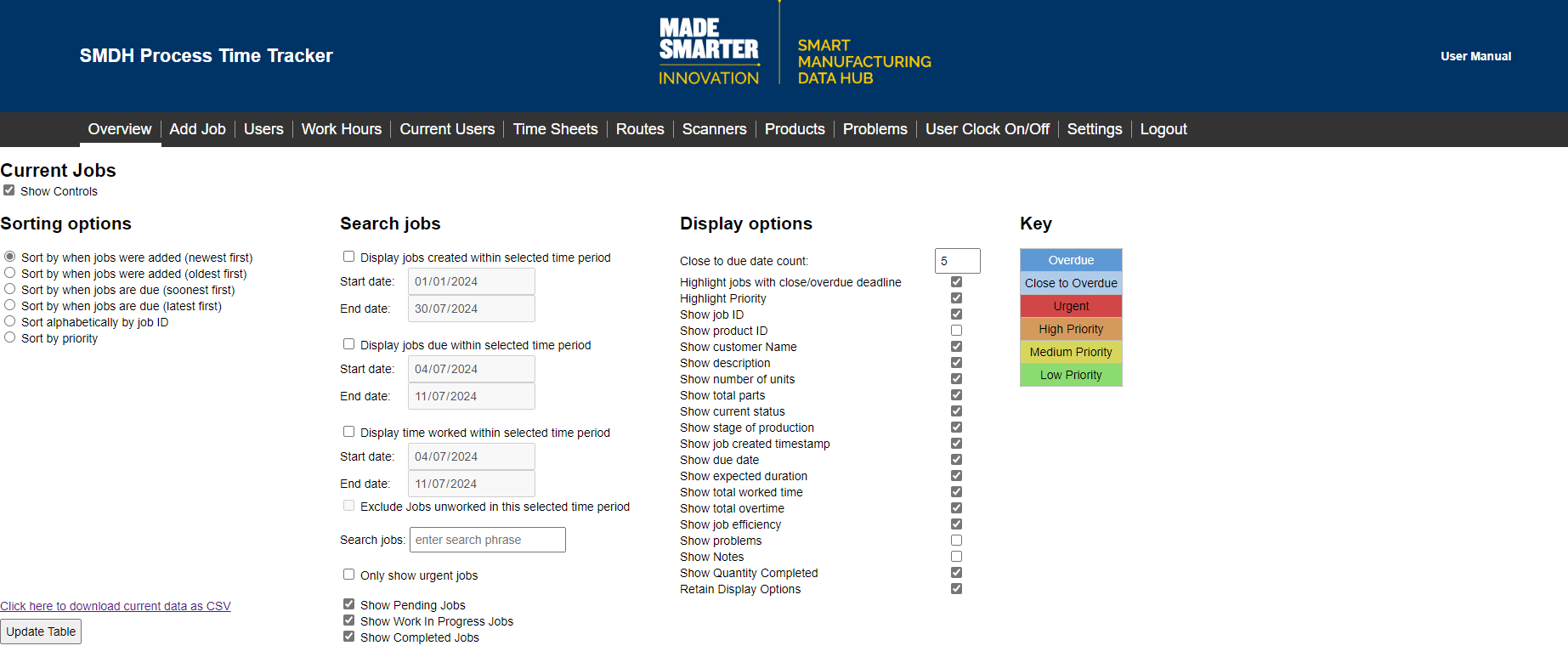

Learn about our Process Time Tracker

Learn about our 3D Factory Simulation

Learn about our HyperSpectroScan Service

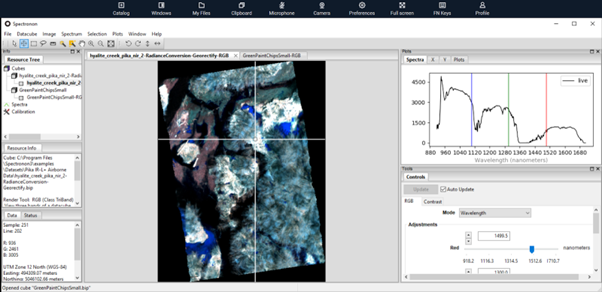

HyperSpectroScan Service

How you benefit from the Hyperspectral Analysis Service

- Comprehensive Data Analysis – Obtain detailed spectral data that reveals more than what traditional imaging can detect, giving you insights into material composition, quality, and more.

- Remote Analysis – No need for complex setups. Send your items to our lab, and we’ll handle the scanning, returning the data directly to you.

- Cutting-Edge Tools – Utilise our VMP-hosted software to dive deeper into the results with powerful post-processing and analysis tools.

Learn about our HyperSpectroScan Service

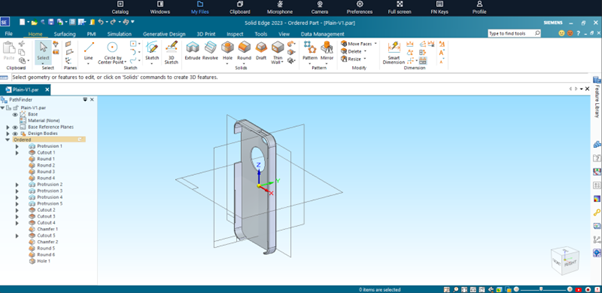

Additive Manufacturing Service

How you benefit from the Additive Manufacturing Service:

- Design Validation – Submit your 3D models for expert review, ensuring they meet manufacturing standards before production.

- Test Prints – We offer prototype printing to validate the integrity, design, and functionality of your models before mass production.

- Cutting-Edge Technology – Utilise our advanced additive manufacturing processes for high-precision and reliable prototypes.