CASE STUDY

Exitex build data driven insights using sensor technology from the Smart Manufacturing Data Hub

Exitex Ltd design and manufacture premium cost-effective weather-proofing, intumescent and acoustic products. They are experts in their field and a trusted partner to many leading names in the construction industry. Their focus is to be at the forefront of innovation and design, supported by ongoing investment in new technology. Learn more about their journey to digitalisation.

Situation

Exitex wanted to improve the efficiency and productivity of their factory processes, achieve energy cost savings, lower their carbon footprint and gain deeper insights into the efficiency of individual machines. Energy costs were of critical concern and the existing single metered data was insufficient to produce an accurate picture of specific energy use in operations. Exitex did not have the ability to capture and analyse the data they needed in order to obtain the clear insights they required.

The SMDH team began to plan how Exitex could capture data on their individual machines' energy consumption and provide analysis to help them to develop a smart factory. Several starting points were identified by the SMDH team:

- The SMDH team identified that energy costs were of critical concern and single metered data was insufficient to get an accurate picture of specific energy use in operations. They had no data to show how much energy their individual machines were consuming.

- Exitex would require a new low cost solution to collect accurate individual machine data.

- Exitex would require analysis of the subsequent captured data.

The Exitex team was committed to improving the usage of data within their business to increase productivity and reduce energy consumption.

Solution

The challenge for the SMDH team was to develop a solution to help Exitex monitor their energy consumption.

The solution was to work with the SMDH partner IfM (Institute for Manufacturing, Cambridge University) and produce low cost power monitoring sensors. This was essential for Exitex to begin their journey towards utilising data to improve their manufacturing processes and reduce operating costs.

The SMDH power sensors clipped on over existing cabling for ease of installation. The sensors were connected to existing Wi-Fi infrastructure and are configured during assembly. The unit was operational as soon as power was applied. Power usage is now transmitted every second to the SMDH secure cloud-based industrial data storage area giving accurate and up-to-date data for management to access. The power sensor is also very compact and was easily installed by Exitex staff, using the instructions provided.

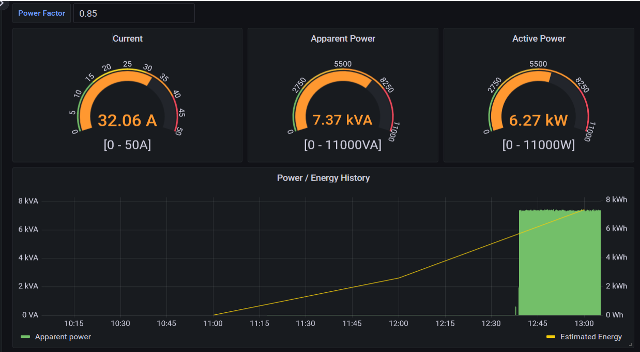

When data was captured and processed, detailed power data analysis was then displayed on specialised dashboards for effective analysis and visualisations.

The SMDH power sensors clipped on over existing cabling for ease of installation. The sensors were connected to existing Wi-Fi infrastructure and are configured during assembly. The unit was operational as soon as power was applied. Power usage is now transmitted every second to the SMDH secure cloud-based industrial data storage area giving accurate and up-to-date data for management to access. The power sensor is also very compact and was easily installed by Exitex staff, using the instructions provided.

When data was captured and processed, detailed power data analysis was then displayed on specialised dashboards for effective analysis and visualisations.

Successes

Introducing the low cost power sensor solution has been a resounding success for Exitex as they can now monitor and measure individual machine’s performance in real time.

The analysis dashboard updates every second, hence the management team can monitor and identify if individual machines are running efficiently. They can visualise complex data on the dashboard which helps identify patterns of power consumption. Therefore, Exitex is now able to calculate the cost of manufacturing one product. The pricing process is now more efficient and accurate.

Management can make data driven decisions to reduce production costs and improve machine efficiency. They can monitor when machines are being used and when they are idle. Exitex are moving towards a data driven approach within their overall business planning and specific targets can be created for production. Exitex understands the benefits of data acquisition for their business and have developed a data culture with employees now aware of the benefits of having access to live data.

Introducing low cost IoT devices (power sensors) onto their factory floor at a low cost through SMDH has removed a major barrier for Exitex to embrace Smart Manufacturing.

Interested in learning more?